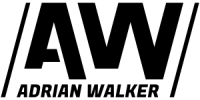

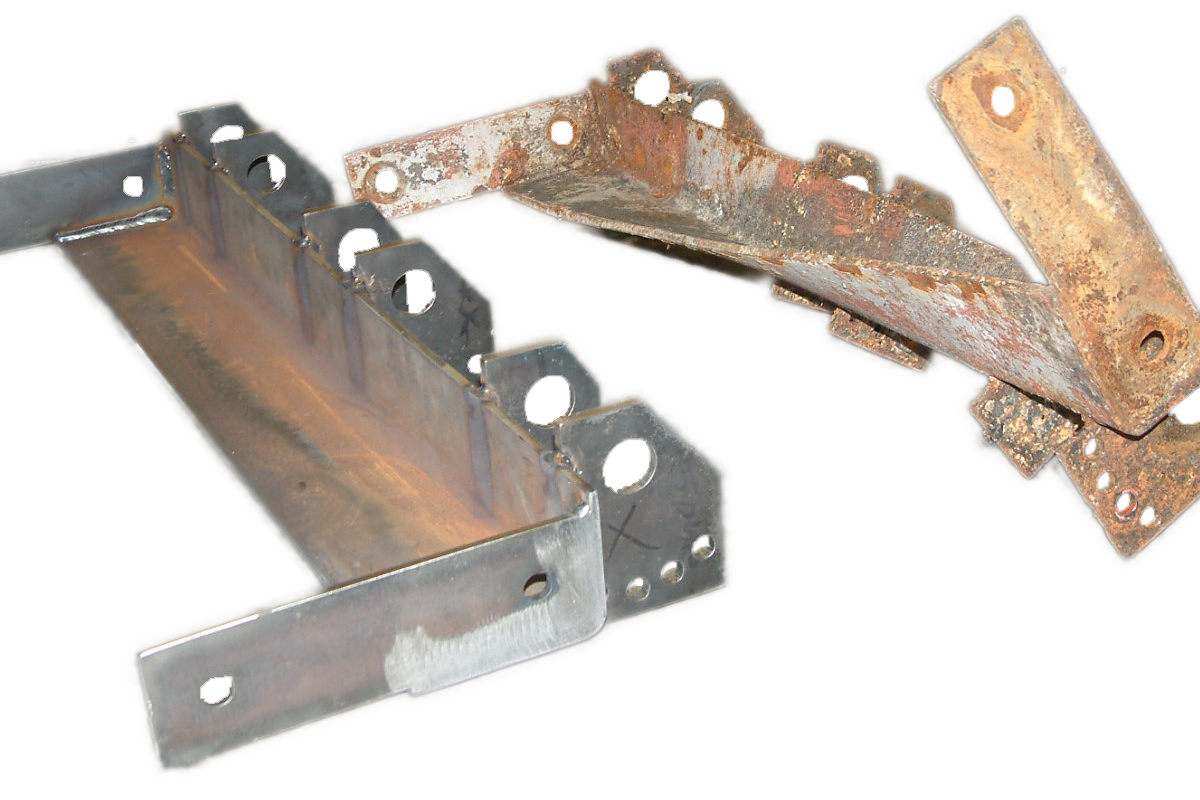

What is reverse engineering? Made from the original this water treatment plant scraper blade was a challenge but with our expert process we focused on the key data and transformed it into a working replacement.

Reverse engineering can really help when old parts need re-manufacturing.

Sometimes a part or an assembly gets damaged or is worn out over time, damaged beyond repair and there is no data or drawings available to manufacture a replacement from.

Adrian Walker can reverse engineer your parts and assemblies, taking our data from the original to be replaced.

This water treatment plant scraper blade had been mangled when some large debris entered the water treatment system.

Although the aging equipment had no drawings or details to have new parts made, we were able to work with what we had been given.

Following this we were tasked with reverse engineering it from the original part.

Water treatment plant scraper reverse-engineered.

Taking our data from the old parts/assemblies

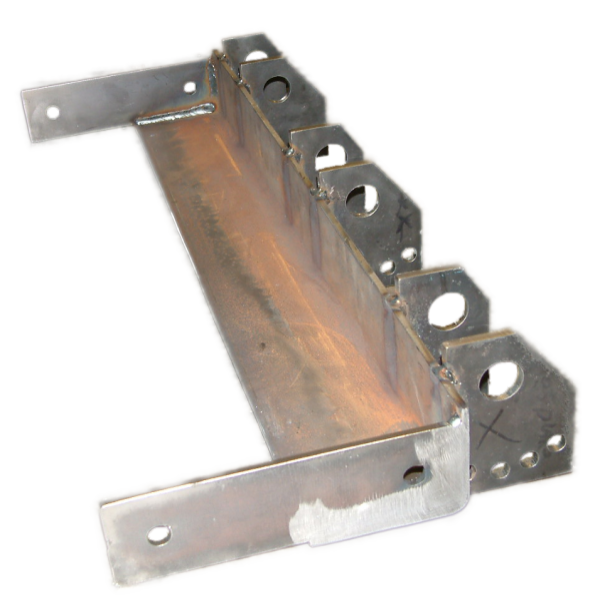

The old assembly of this water treatment scraper blade was rusted, twisted, and worn.

Utilising a variety of methods, we were able to reverse engineer the part by taking our data from the original and working out the dimensions from the old parts.

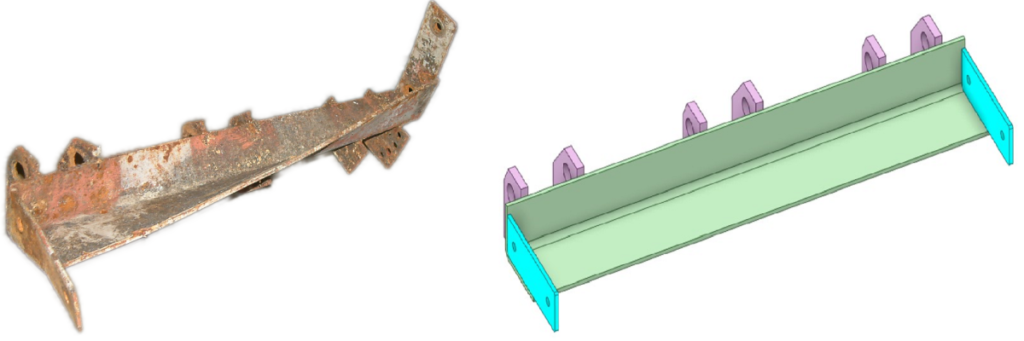

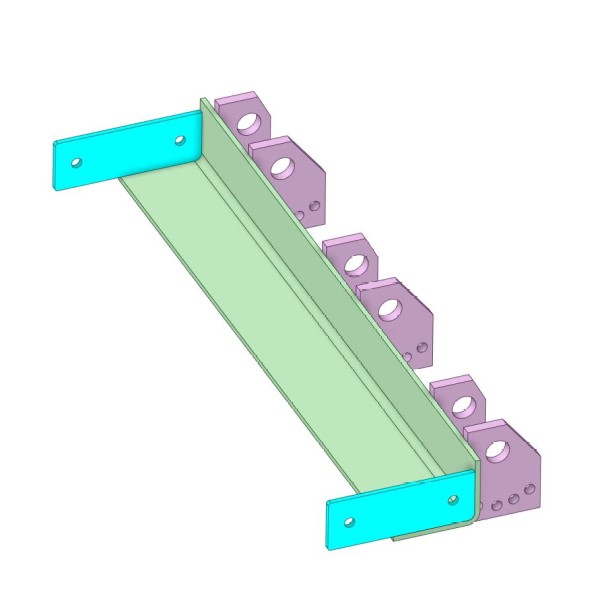

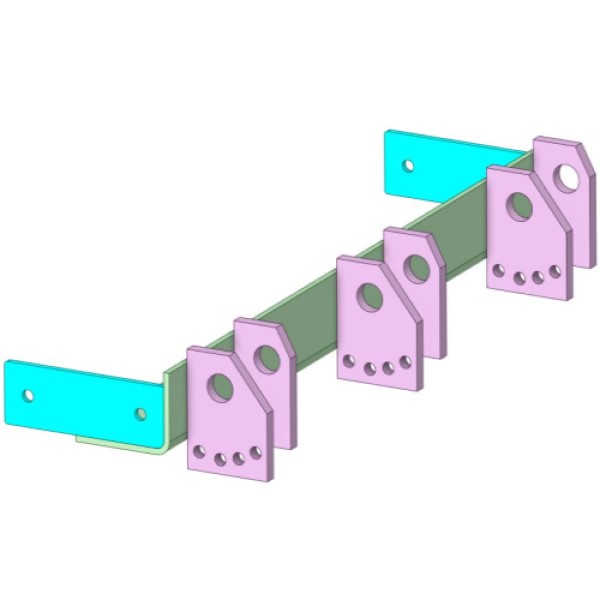

We will remodel the parts and assemblies in 3d cad

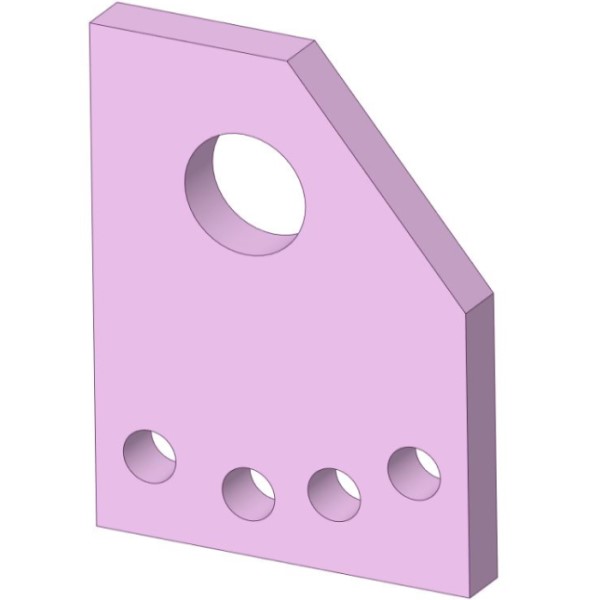

Once we had the reversed engineered data in hand, we set about modeling up the parts in 3d cad, ready for manufacture.

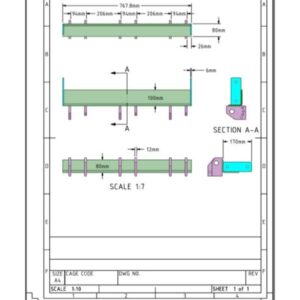

Following the creation of the part models we can then create the digital assets for the parts to be manufactured from.

This will be either 3d cad solid files or cad drawings.

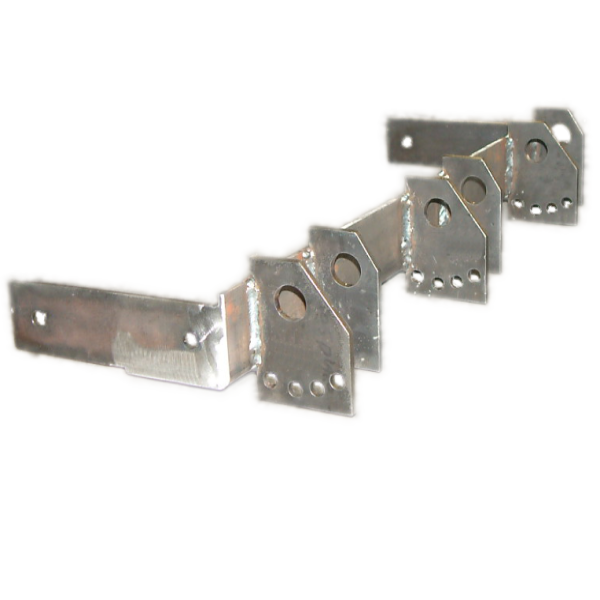

From our drawings and cad files new parts and assemblies can be created

Once we have created the cad files and data we can either supply you the data so you can get the items manufactured in your workshop or from your suppliers.

Or we can offer quotes from one of our associates and look to supply you with the finished parts/assemblies as well.

The full reverse engineering process

Ultimately we can turn our old part into a new part as shown above from left to right you can see the full reverse engineering process.

Consequently seen above from the original mangled assembly on the left to the remodeled 3d cad assembly in the middle and the finished replacement on the right.

The technology used for reverse engineering

- Digitising: Using a combination of 3d scanning, laser scanning, and photogrammetry to get our data we can make sure we capture the details we need to work from on your job.

- 3D Software: We can take our scanned data or digitised images and work with them in our software to get the data we need to then remodel the parts in 3d cad.

- Digital assets: We will create the required digital assets from Cad software in the form of solid 3d models or, cad drawings or PDF files.

Have you got a project or problem to solve? contact Adrian Walker for a solution

Detailed design work by Adrian Walker.

What will your project be?

J786