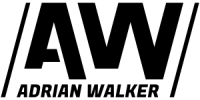

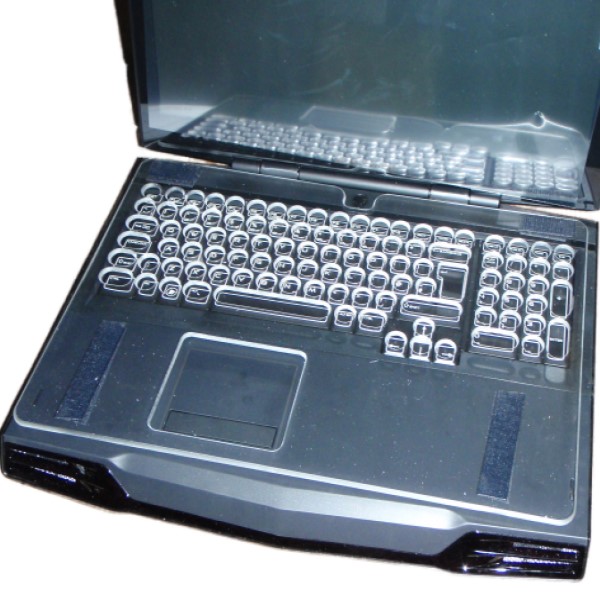

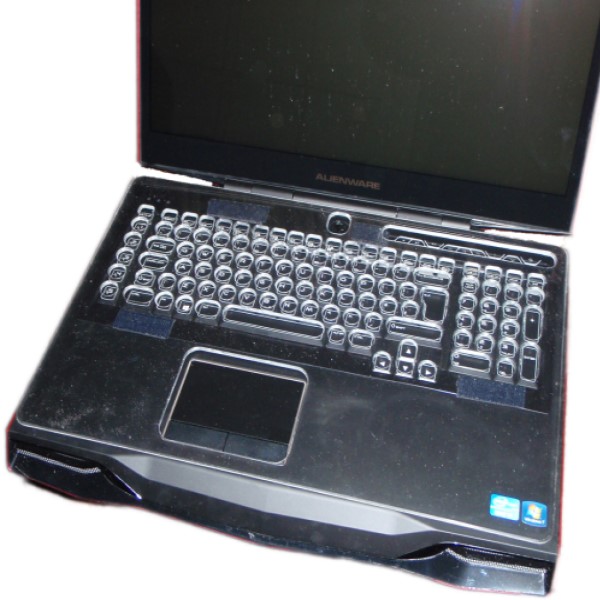

Keyguard/keyboard cover manufactured to aid people with disabilities

Operating a keyboard can be very difficult for people with certain disabilities like cerebral palsy or impaired vision when you’re trying to press certain keys other keys can also be unintentionally activated at the same time.

Adrian Walker will digitise your keyboard or laptop and design a cover in 3d cad.

Utilising this design, a made-to-order Keyguard cover will be manufactured.

Keyguard / keyboard covers are held onto the laptop / keyboard with velcro for easy use or removal.

Machined with smooth reduced openings means a hand can sit on top without activating the keys below and a small recess precision machined in the correct location allows the tip of a finger to press the intended keys as required.

Samples of custom keyguard / keyboard covers we have produced in the past:

How does this custom service work?

Start off by sending us an initial enquiry by email.

Include a couple of pictures of your laptop or keyboard with some dimensions.

Ideally, send a picture with a tape measure in the background for reference.

When you email the details also include any special requirements.

Upon receipt of the information, we will work out a quotation and email you back.

Once we receive the order and your laptop / keyboard we will start to process the job firstly by digitising or scanning the keyboard so we have a digital representation of it.

We will then design a keyguard / keyboard cover to fit on the keyboard.

In most cases, this will be a machined flat acrlyic sheet held on with Velcro tape so it can be used and removed easily.

But depending on your keyboard / laptop if it has complications like raised keys or closely grouped keys we will try to design around these.

Prior to manufacture we will send a pictorial proof for you to agree on.

The technology used for custom manufactured keyguard / keyboard covers

- Digitising: Using a combination of 3d scanning, laser scanning, and photogrammetry to get our data we can make sure we capture the details we need to work from on your job.

- Machining: We will have the parts machined from Acrylic (other materials could potentially be used) ensuring that all sharp edges have been de-burred for smooth finger entry holes

- 3D printing: When required and to overcome issues we may also use 3d printed parts.

Have you got a project or problem to solve? contact Adrian Walker for a solution

Detailed design work by Adrian Walker.

What will your project be?